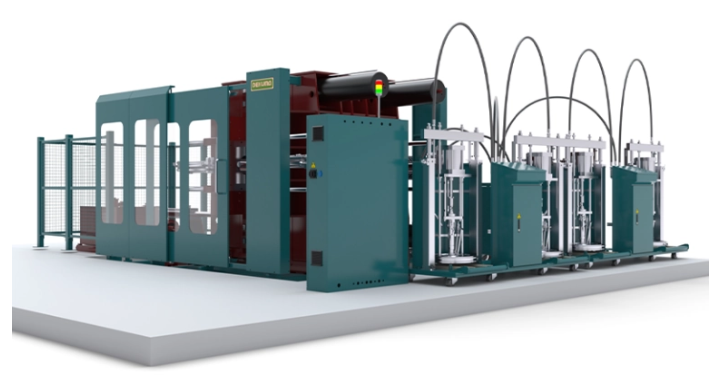

In the world of silicone molding, choosing the right process and material is crucial for achieving optimal results. The key difference lies in the material state and process. LSR is liquid at room temperature and injected using a liquid silicone rubber injection molding machine, which includes dosing pumps and static mixers. In contrast, solid silicone (HTV) requires pre-forming and higher compression forces, often processed in Solid Silicone Rubber Molding Machines. Leading brands like Dekuma provide innovative solutions tailored to various industries.

Applications of LSR Injection Molding Machines

LSR injection molding machines are widely used in several sectors, including medical, infant care, electrical, and consumer goods. In the medical field, applications range from catheters to masks, where precision and biocompatibility are paramount. Likewise, in infant care, products like nipples and pacifiers benefit from the soft, flexible nature of LSR, ensuring safety and comfort for babies.Additionally, LSR injection molding machines find applications in electrical components, such as insulators and cable seals, where durability and resistance to heat are critical. In the consumer goods sector, items like kitchenware and gaskets leverage the advantages of LSR to provide high-quality, long-lasting products. Dekuma, a leading LSR injection molding machine manufacturer, offers systems designed to meet the unique needs of these diverse industries.

Choosing the Right LSR Injection Molding Machine

When selecting an LSR injection molding machine, it’s essential to consider factors such as production volume, part complexity, and the specific material requirements. Dekuma excels in providing tailored solutions that enhance productivity and efficiency. As a trusted LSR injection molding machine supplier, Dekuma’s expertise ensures that manufacturers can optimize their processes for maximum output.

Conclusion

Understanding the key differences between LSR and HTV silicone molding processes is vital for manufacturers. With the right LSR injection molding machine, businesses can unlock new possibilities in product development across various sectors. Trusting a reputable supplier like Dekuma can significantly enhance your production capabilities and product quality.