Lithium-Ion battery manufacturing is evolving rapidly, and the right equipment can make all the difference. Among the leading brands in this sector, LEAD stands out with its innovative solutions tailored for prismatic cells. This article explores the latest advancements in Lithium-Ion battery manufacturing equipment, particularly focusing on formation and aging processes.

Innovative Formation Solutions

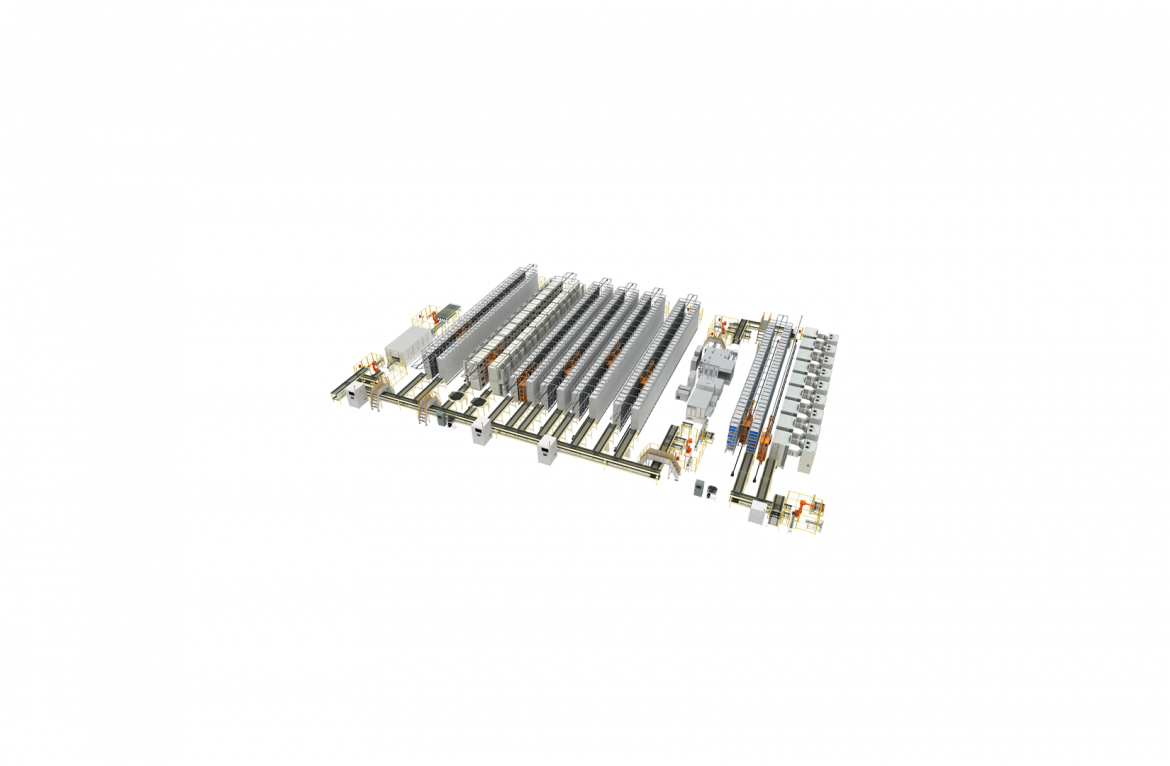

The formation of Lithium-Ion batteries is crucial for performance and longevity. LEAD has developed cutting-edge Lithium-Ion battery manufacturing equipment that enhances the formation process for prismatic cells. By utilizing vacuum assemblies attached to compression trays, LEAD ensures a more controlled environment, leading to higher efficiency and improved battery quality.

Aging Process Optimization

Aging is another vital aspect of battery manufacturing. The aging process helps in stabilizing the chemical properties of the cells. The Lithium-Ion battery manufacturing equipment from LEAD incorporates advanced technology to optimize aging, ensuring that batteries maintain their performance over time.

Cleanroom Technology

Traditionally, cleanrooms are essential for formation workshops. However, LEAD has revolutionized this concept by integrating vacuum formation chambers that utilize water-heating exchangers. This innovative solution not only controls internal temperatures with high accuracy but also enhances personnel comfort, making the workspace safer and more efficient.

Conclusion

As the demand for Lithium-Ion batteries continues to rise, investing in advanced Lithium-Ion battery manufacturing equipment is essential. LEAD leads the way with its innovative solutions for formation and aging processes, ensuring that manufacturers can produce high-quality batteries that meet the market’s growing needs. Embrace the future of battery manufacturing with LEAD and stay ahead in this competitive industry!