Edge banding is a vital step in woodworking, ensuring the panel edges are smooth and durable. The HUAHUA CNC edge banding machine is designed to enhance this process with its advanced features, including servo-controlled adjustments and high-speed cutting systems. This article discusses how to use the automatic edge banding machine efficiently, ensuring top-notch results for your woodworking projects.

Understanding the Components of the HUAHUA CNC Edge Banding Machine

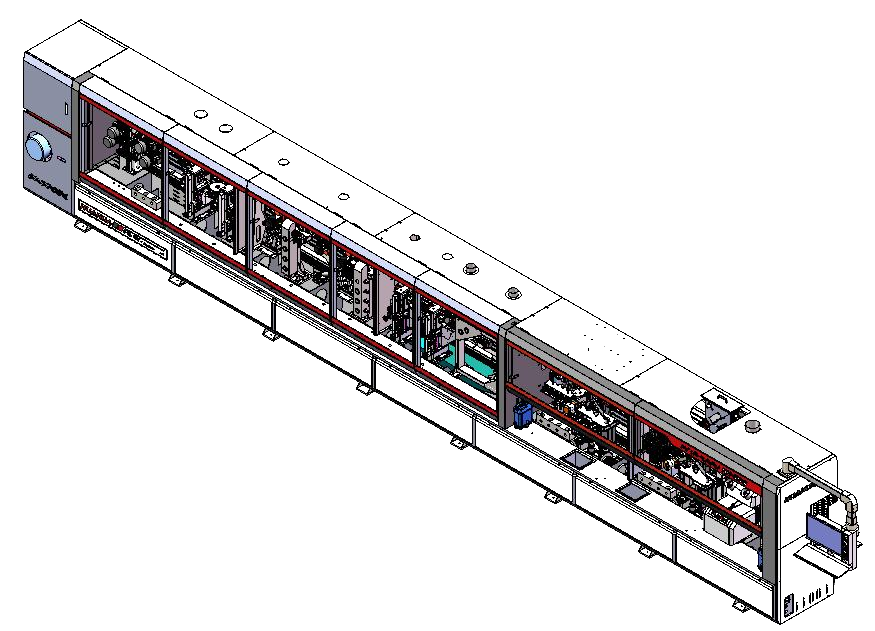

The HUAHUA CNC edge banding machine consists of several key components, each contributing to the overall quality and efficiency of the machine. The servo adjustment guide plate allows for precise control, while the pre-milling motor with a 3.7KW capacity ensures smooth panel edges before applying the tape. Furthermore, the automatic edge banding machine utilizes a four-channel glue feeder that delivers an even, consistent layer of glue for secure edge bonding.

Step-by-Step Process of Using the Automatic Edge Banding Machine

To begin using the automatic edge banding machine, start by adjusting the machine’s settings for the specific panel size. The servo-controlled tape feeder and glue pot should be calibrated to apply the right amount of adhesive, and the tape width should be set between 13-63mm. After feeding the panel into the machine, the servo-driven pressing mechanism ensures that the edge tape adheres firmly. The final steps involve rough trimming, fine trimming, and cleaning for a seamless finish.

Tips for Maximizing Efficiency with HUAHUA CNC Machines

Maximizing the efficiency of the HUAHUA CNC edge banding machine involves maintaining the machine regularly and adjusting settings according to the material and thickness of the panel. For example, using the servo multiblade scraping system ensures smooth and consistent edge profiles, and the pneumatic scraping system minimizes glue residue on the panel. Additionally, ensuring that the glue application and pressuring mechanisms are aligned will reduce the need for rework.

Conclusion

The HUAHUA CNC automatic edge banding machine offers excellent versatility and precision for edge banding applications. By understanding the machine’s components and following proper setup and maintenance practices, operators can ensure a smooth workflow, improve product quality, and extend the machine’s lifespan. Whether you’re working with wood panels or composite materials, this machine will help deliver professional results.